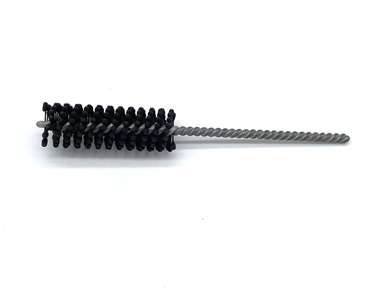

Application of Boron Carbide Brush Hone Tool

Boron carbide brush hone tool is one of the industrial brush types, suitable for grinding various types and sizes of cylindrical parts, after the soft and soft abrasive stone tool treated metal surface effect is unmatched by other tools. The whole process includes a complete treatment of the geometric arrangement of the surface and the metallographic organization of the object. The treated surface is completely free of scratches, tears, or folded metal.

Features of Boron Carbide Brush Hone Tool

A rebounding, flexible sanding tool that finishes in a relatively gentle manner. Its unique construction allows the ball to float, which ensures that the tool is self-centering and self-adjusting as it works through the hole, and can counteract wear on its own.

Whether you need cross-hole sanding, surface preparation or edge sanding, there is a soft grinding stone tool for you. Whether used in automotive production, aerospace, marine or other industrial applications, soft grinding stones have created a superior surface that has improved the performance, longevity, and compliance of many products.

The soft grinding stone tool removes bumps and other imperfections from the barrel walls, thus creating a satisfactory surface finish. The result is a soft-abrasive surface that reduces localized overheating or excessive friction, resulting in better performance of the part.

en

en