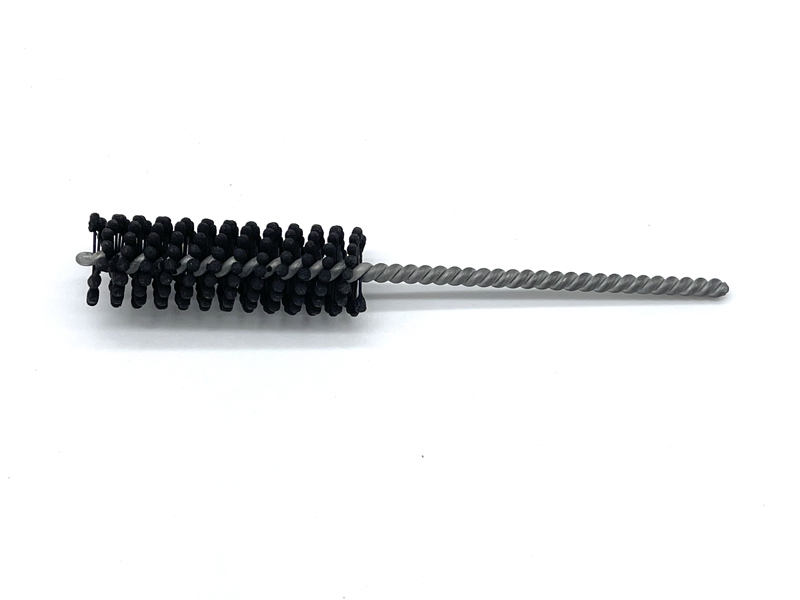

Silicon carbide honing brush is the most common kind of honing brush, the hardness of silicon carbide crystal is very high, at the microscopic level, the crystal is very sharp and has excellent acid and alkali resistance, especially suitable for processing cast iron, steel and quenched parts and other high hardness of the workpiece or other non-metallic materials. At the same time, the price of silicon carbide is relatively low, with a high cost performance. The common abrasive mesh number is 120#-320#.

en

en